Case Study: Online Learning for Design and Calculation of Machines

- 1Department of Applied Mathematics, University of Salamanca, Salamanca, Spain

- 2Department of Mechanical Engineering, University of Salamanca, Salamanca, Spain

- 3Department of Chemical and Textile Engineering, University of Salamanca, Salamanca, Spain

In recent years, the University of Salamanca together with other 45 European universities have changed our university qualifications, resulting in substantial changes in the system of education. In this case study, we detail the particular case of the subject of Design and Calculation of Machines of the Degree in Mechanical Engineering, which is given at the School of Industrial Engineering at the University of Salamanca. The use of technological tools and resources to make students acquire the desired competences suppose a change in the learning paradigm. The more traditional teaching system changes to become a self-learning system. With the files, tasks, and activities available on the web platform, students could follow their own learning. We include data related to the improvements in the students’ marks.

Introduction

Because of the changes in the Industrial Engineering Degrees curriculum, according to the guidelines of the Bologna Accord (EHEA, 2010), monitoring student’s learning is required. To implement more effectively, the system of continuous assessment and competence-based learning, and to track subjects a Moodle-based learning management system (LMS) is used. Many of the Spanish universities use this virtual learning environment (Moodle, 2012). Besides the more theoretical notes and presentations, problems statements with their solutions are included on the online platform. One of the advantages of online environments is that they can be accessed from any place and at any time. Our virtual learning environment includes proposed problems, some of which are solved during classes’ time, and the rest are solved entirely with explanations and graphics, and are available for students on the LMS. Likewise, some links to videos are also available for students, to have a better view of the subject and its eminently practical application. One of the advantages of the online platforms and e-learning system is that they allow students to build their own learning (Gogan et al., 2015).

This paper describes the case study of Design and Calculation of Machines subject, included in the sixth semester (out of eight) in the Mechanical Engineering Bachelor’s Degree, at the University of Salamanca (Spain).

In recent years, our laboratories have been limited by economic factors due to the high cost, maintenance, or renewal of equipment. The restriction on the use of the laboratories is linked to the necessity of the presence of the head teacher which means the under-utilization. There is also a spatial limitation due to the increase in the number of students, so it is not possible to offer a laboratory post for all of them simultaneously. Sometimes we change on-site laboratories for simulations and virtual laboratories, as was proposed in Buitrago-Molina et al. (2014), they developed a system to allow a remote control of the SCARA robot arm, and it was made using a virtual platform. One of the simulation software that we use is Autodesk Inventor (Younis, 2010), because of the tools included in this program for the mechanical design and simulation. Simulations are educational tools that are used in the context of the so-called education based on the simulations, which could be defined as any educational activity that uses the help of simulators in order to stimulate and promote learning through a more or less complex virtual scenario (Poindexter and Heck, 1999; Bencomo, 2004; Ko et al., 2004; García-Beltrán, 2006; Torres et al., 2006). The use of simulations in different contexts is not new. In fact, the simulations have been used for some time in different fields. We could cite as examples the nuclear power plants that have had since the beginning security management programs based in simulation. In those plants, the knowledge of the nuclear reactor and its behavior before a nuclear crisis is tested regularly by simulation. In the case of airline industry, simulators are also used in the training of airline pilots. In fact, the first flight simulator appears in 1929, introduced by the American engineer Edwin A. Link, who marketed the so-called “Blue Box” or “Link Trainer” (Link, 1930). In these two contexts, the use of simulations always has the same underlying principles: ensure safety and prevention of critical errors. Our students, as future engineers, they should be familiar with simulation tools. The undergraduate students who learn can contribute positively to professional development. Computer-assisted tools improve students’ spatial vision, mental environment manipulation, and the abilities to visualize the results of their work (Robertson et al., 2007).

In most of the course modules, students must perform a questionnaire, which includes the fundamental concepts. The time to complete this questionnaire is limited and both the questions and possible answers will arise randomly for each student in order to be carried in an entirely individual way. This mechanism has given us very good results in the subjects worked so far. One could check the level of assimilation of the necessary concepts needed for understanding the following course parts.

At the end of each course’s part students should complete a survey with several questions related to the learning pathway, and their difficulty in understanding all the concepts, and the needed time to complete the course.

This blended learning system, which includes classes and online learning, is especially useful in our Engineering School, because there are many students from some villages far from the school. This LMS will include lectures, assignments, tutorials, projects, laboratories, and technology enhanced learning; these will be related to the acquisition of industrial engineering competencies. Furthermore, several basic and transversal skills and competences will be developed to contribute to the development of a European area of common education.

In recent years, we have analyzed the results obtained from the use of Moodle with several basic subjects of different degrees of industrial branch; in particular, the case of mathematics for engineers, numerical methods, algebra or calculus, see, for example Caridade et al. (2015), and we have also studied the motivations for undergraduate students (Queiruga Dios et al., 2013), but in this research the aim is to study the case of a specific course in mechanical engineering degree. The minimum training contents of this field are: fundamentals of machine design, selection of typical machine elements, and applications of machine design computer aided. Some of the skills, abilities, and competencies included in this subject are to get an integrated view of the mechanical elements and machines or be able to design typical machine elements and select materials, processes, and treatments for specific applications. Those aspects make this subject especially interesting for a detailed analysis.

The learning arrangements are based on the acquisition and development of the specific competence: acquisition of knowledge and techniques for the calculation, design, and testing of machines. For specifying and measuring progress on such competence the use of technology and open educational resources are of great importance.

This paper is organized as follows: Section 2 describes the methodology and tools for Design and Calculation of Machines course, including the organization of the course and the IT tools used to teach and learn. Section 3 details the assessment and evaluation procedures for the subject, and finally the conclusions are shown in Section 4.

Methodology and Tools for Design and Calculation of Machines Course

Design and calculation of machines subject is mainly experimental, but its study is based on a previously acquired knowledge in other three disciplines: mechanisms, elasticity and materials resistance, and materials science (Mott, 2013). Those are more theoretical but are also based on the experience. Without this previous knowledge, it is impossible to overcome the course and to acquire the suitable competencies and skills.

Competence-Based Structure and Organization of the Course

As was mentioned before, the specific competence (from mechanical engineering branch) that students will acquire after assisting the course is knowledge and techniques for calculation, design and testing of machines.

The general competences included in this course are

• Understanding and interpreting texts and data, developing skills for their concreteness and the exposition in clear and simple terms.

• Aptitude for the distribution of resources and time and its implementation in real situations.

• Capacity for the use of scientific-technical tools for solving computing and design in industrial engineering problems.

• Ability to set and ability to develop multidisciplinary projects.

The learning outcomes included in this course are

• Brief overview: introduction to machines, stresses and deformations, and materials.

• Theoretical concepts of machine design: elements under static load, materials under fatigue loading.

• The identification of the various machine elements: Axles, Lubrication and sliding contact bearings, gears, and mechanical springs.

The training activities are separated into

• Large Group Activity: exhibition, explanation, and exemplification of the contents. Lecture and solving exercises by the professor.

• Media activity group (maximum 30 students): troubleshooting and/or practical cases.

• Small group practice activity (maximum 15 students): practices, workshops, and specialist lectures and seminars about theoretical and problems classes.

• Seminar (maximum 15 students): seminars protected. Presentations where complementary specialized themes are developed, and where the students participate actively.

• Tutoring: individual or group, personal monitoring of student learning.

• Online and distance activities: personal study, preparation of reports, problems solving, team works, and exams preparation.

Methodology with IT Tools

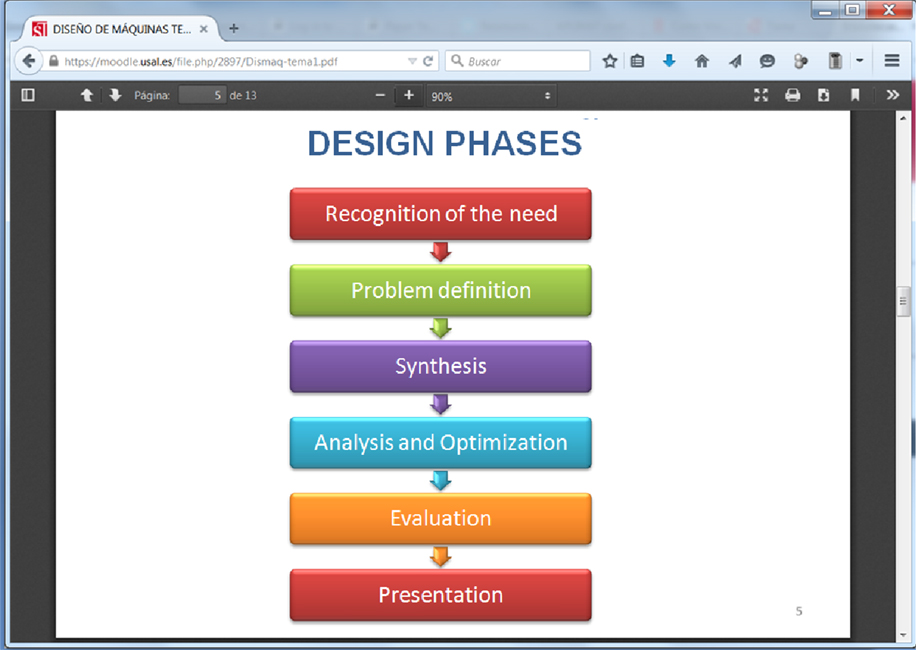

The Moodle (Modular Object-Oriented Dynamic Learning Environment) platform facilitates the spreading of the course contents (Martín-Blas and Serrano-Fernández, 2009; Escobar-Rodríguez and Monge-Lozano, 2012), together with a wide collection of proposed problems and some of them included with the detailed solution (Norton, 2006). Clearly, one of the advantages of a LMS is the possibility of keep available all the schemes and files as often as necessary. For example, in case students want to check the scheme of the mechanical design phases, they could access to the file with the introductory track (see Figure 1).

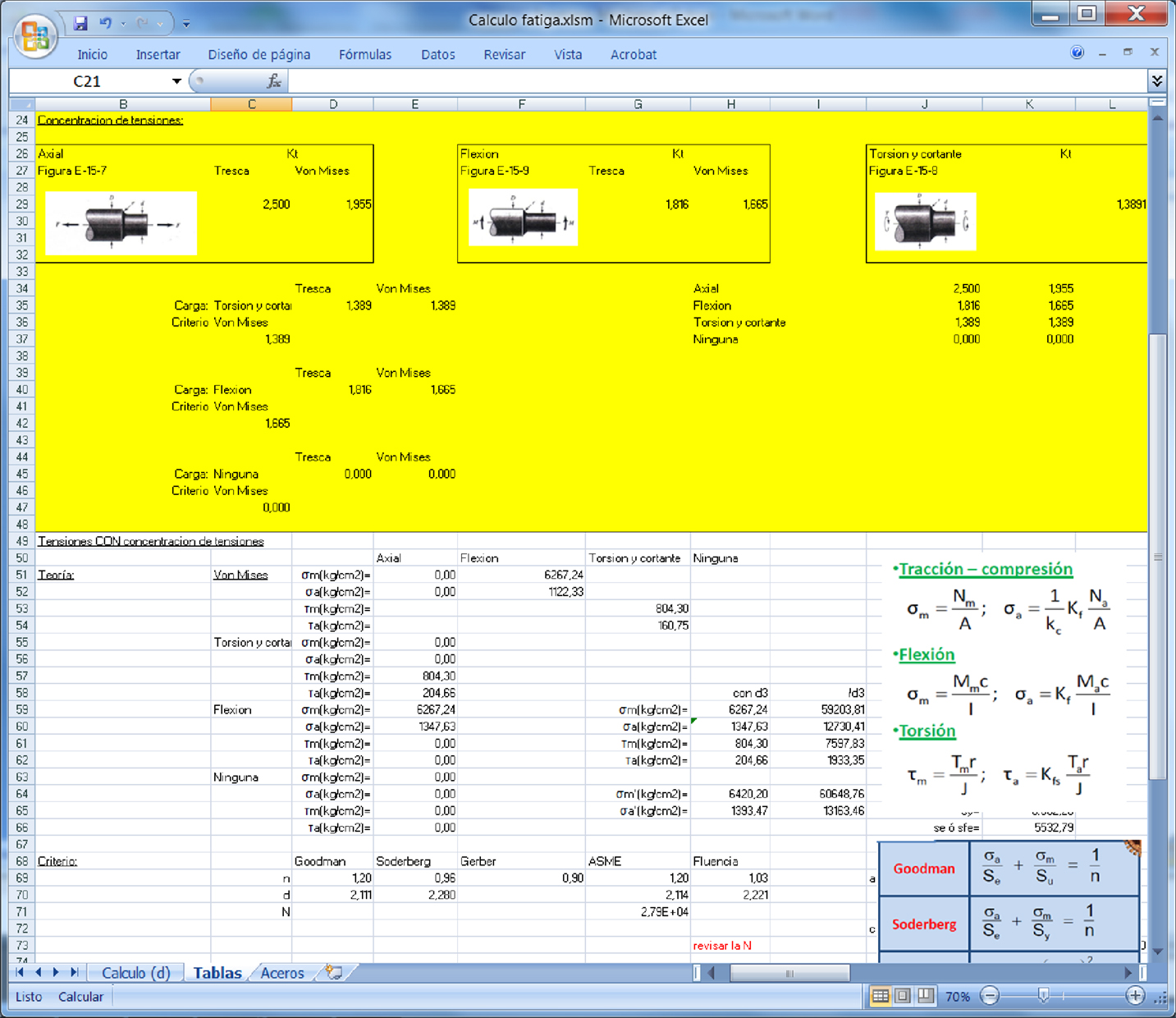

On the particular case of the verification of the results of axes submitted to fatigue students are provided by an excel sheet that includes the graphics and tables with the materials properties and stress concentration to solve the problem. Figure 2 shows an example of the excel spreadsheet used to solve some proposed problems (Reshetov and Weinstein, 1978). In addition to perform simple and complex calculations, and to help accountants to solve their accounting problems (Cheetancheri and Cheng, 2009), a spreadsheet may also be used for educational purposes to simulate behaviors of different dynamical systems (Ibrahim, 2009), to design worm gears or machines, or to analyze aircraft structures. Excel spreadsheet could also be integrated into several software to develop a complete tools, like the one proposed by Cheetancheri and Cheng (2009) for kinematic and dynamic analysis, graphical plotting, and animation for four bar, crank-slider, five bar, and six bar linkages.

One of the major advantages of Moodle platform is the possibility that the students could fill questionnaires and quizzes in order to assess their level of knowledge, in addition to carry out some satisfaction surveys and surveys to evaluate their own classmates. Furthermore, WIRIS (http://www.wiris.com/) as computer-based assessment tool is also available to improve those questionnaires (Queiruga Dios et al., 2012). This tool allows professors and trainers to add and modify questions, including random values and computer operations inside a questionnaire’s question. Some possibilities of our questionnaires are

• Questions can include graphical representation of curves that shows the different solutions from a problem.

• The statement numbers of the proposed problem could be different to each student.

• The online calculations could be done in the same computer.

• The questions and possible solutions can be randomly presented.

For the accomplishment of the questionnaire from every block students have 3 days with only one attempt. Each questionnaire includes 10 questions related to the topics of the block. To solve these 10 questions, the time is limited to 1 h, enough time to carry out the necessary calculations.

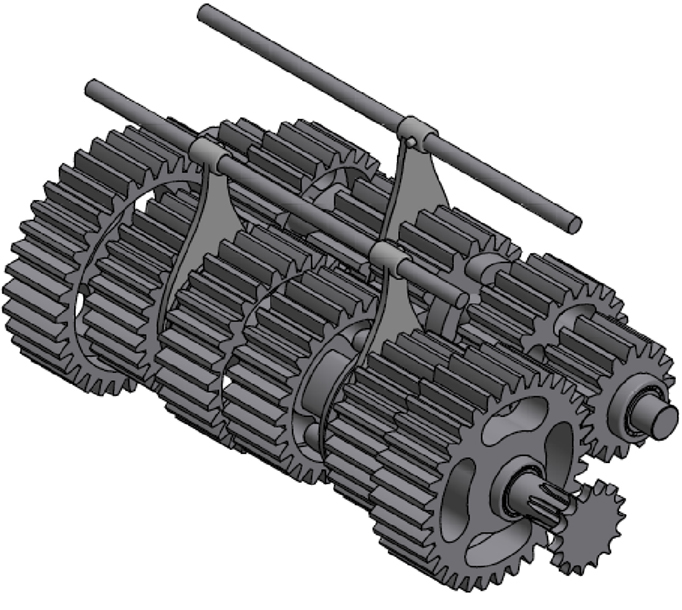

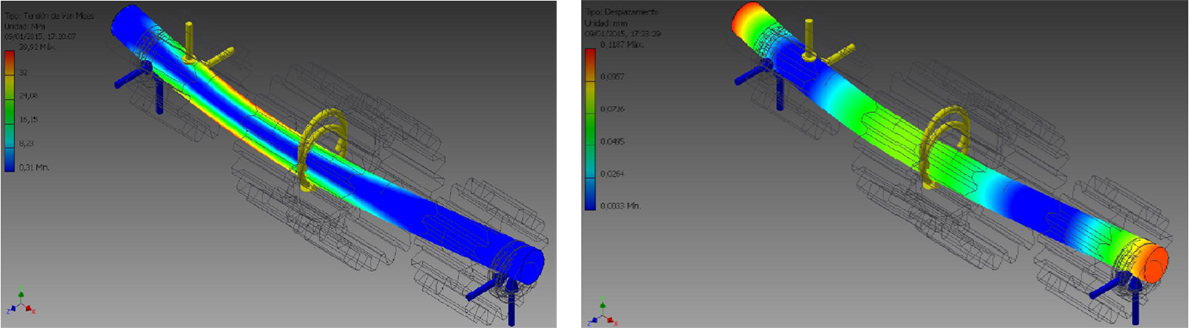

In this way, it is possible to offer the engineering students’ more and more complete and deep formation in mechanics. It allows them to face their future professional activity, adapting to the advances of science and technology. The use of Autodesk Inventor as simulation software (see Figure 3 as an example), allow the creation of virtual laboratories to facilitate the experiments by simulating physical phenomena and mathematical models.

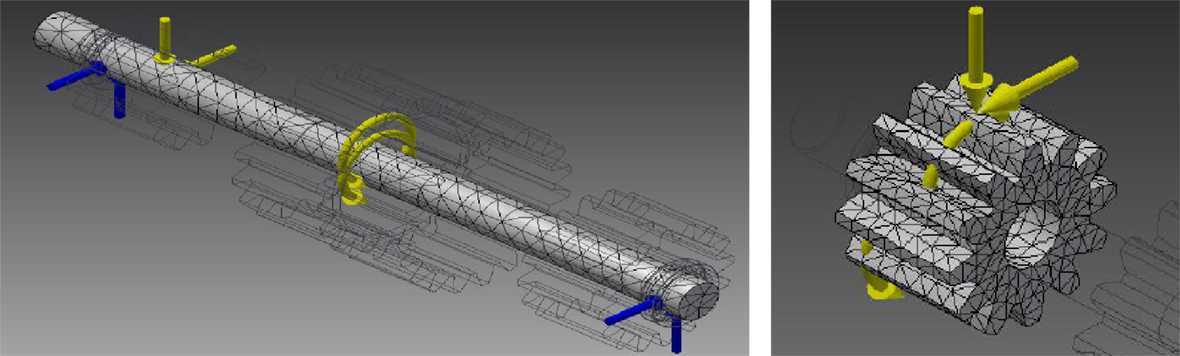

Autodesk Inventor allows students to make a detail design of all the components of a real motorbike. The first step is to make a sketch and define the grid intervals. For the case of the primary shaft and the gear for first speed for the same gearbox the result is shown in Figure 4.

After that, students could analyze the stress and the strain along the primary shaft, getting an image like Figure 5.

Simulation tools have some advantages:

• Allow more students to work at the same time.

• Eliminate potential risks experiencing as many times as necessary (to obtain the required competences).

• Flexible schedules: students can develop the simulation at any time and from anywhere; providing an enabling environment for self-learning.

• Enhances viewing simulations of dynamic objects and phenomena, developed in Java (as Java applets), Flash, CGI, PHP, etc., including images and animations using a simple browser interface.

As a result of our ICT-based teaching, we have adapted our classes to the new educational paradigm where the student is the center of his/her learning process. The student is the responsible of the acquisition of knowledge and contents. The way we do it is personalizing the learning through the use of IT tools, adapted to the needs and progress of the students (Alonso et al., 2005).

Assessment and Evaluation

Due to the fact that this subject is basically practical, the resolution of practical exercises and problems is a fundamental part. To be able to interpret adequately the results, the students must have a clear knowledge of the theoretical concepts. Consequently, the virtual learning environment has several questionnaires focused on the minimum necessary level, besides the summaries of all the topics of the subject, as well as a great collection of proposed and solved problems (Mischke and Shigley, 1972). The students also have some links to connect to Internet pages where they can see the operation of different elements of machines.

The classes with the use of the virtual environment favor a more individualized teaching–learning process adapted to each student. At the beginning of each course, we ask students if they want to change the traditional system to a different one based on their continuous and individual effort. They could choose between the proposed activities or to get the final mark with a final term exam. All of them agree with the new system, as they want an active participation on the learning process.

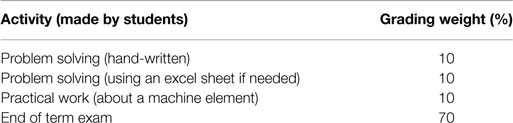

Continuous assessment of students includes the sections detailed in Table 1. The assessment of the practical work includes written work (10%), contents (30%), references (20%), and oral presentation (40%).

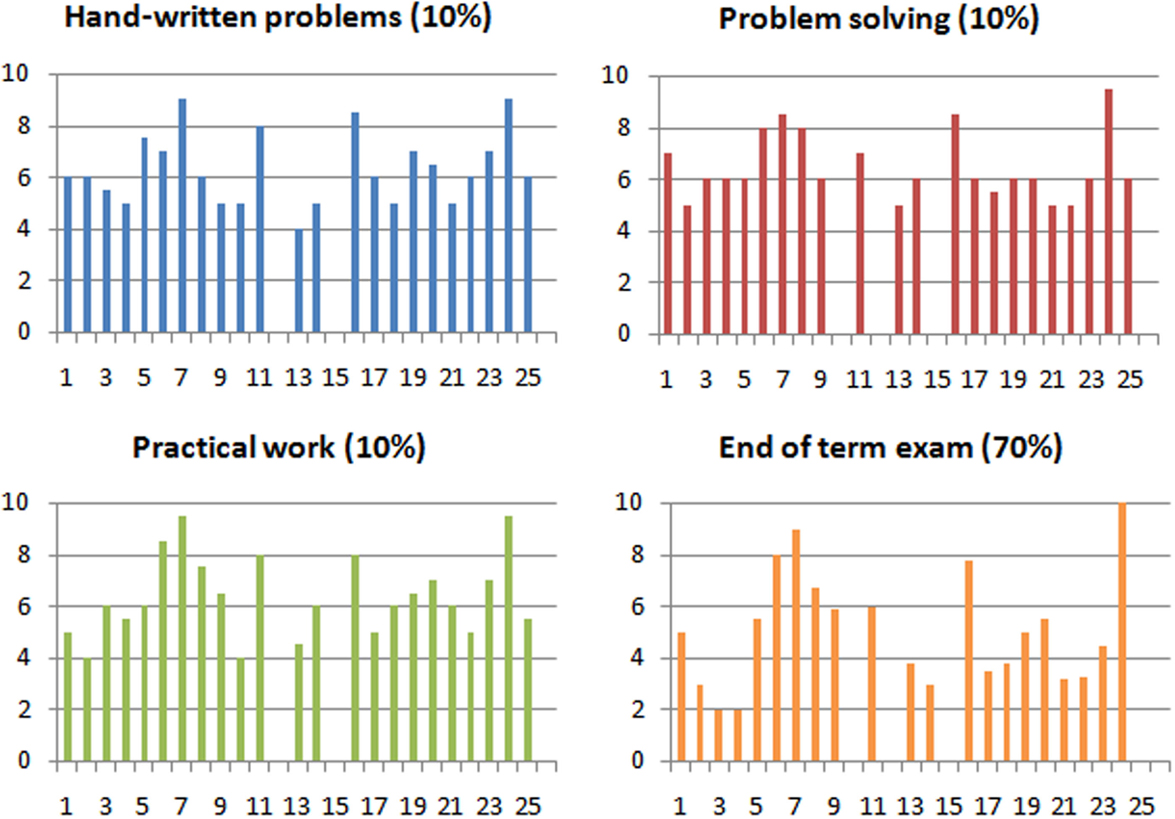

During the last 2014–2015 academic year, the results for those activities are shown in Figure 6. We appreciate very good results, because students participate actively in this system.

The practical work about machines could be individual or in teams, students use some simulation software, such as Autodesk Inventor©. The possible topics are

• Cushions of rolling contact.

• Screws and spikes and elements of union.

• Mechanical transmission with flexible elements.

• Clutches and brakes.

After the work exhibition, students evaluate one another (peer-to-peer evaluation), using a rubric available on the Moodle platform. This rubric was created to help students to know the evaluated issues such as exposition, topics knowledge, skills acquisition, and so on. This tool serves as reinforcement to students as they have to evaluate themselves. Thus, they gain more experience and are more aware of what is valued, for example, when making a workgroup or a lecture in public.

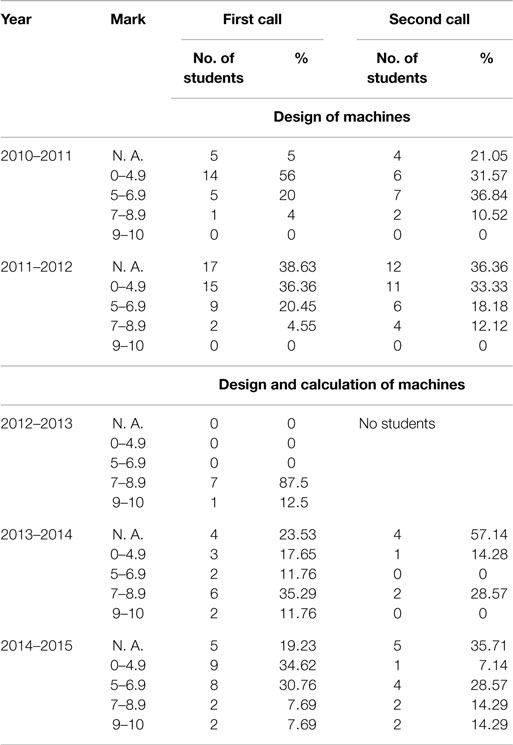

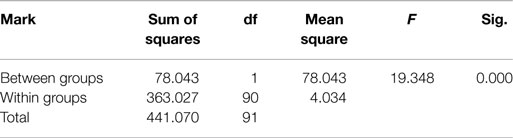

This method of continuous assessment has been used during the last two academic years (2013–2014 and 2014–2015), with a high acceptance rate by the students. We have included in Table 2, the final marks from those years, and also from the previous 2010–2011 and 2011–2012. Before the changes in the Industrial Engineering branch degrees, according to the Bologna Accord (EHEA, 2010), the course of Design and Calculation of Machines was called Design of Machines and the classes did not include neither computers, nor technological procedures or virtual tools. The more traditional on-site classes did not get as good results as we have nowadays. The “Mark” column is related to our measuring system: N. A. means “Not Attended,” and the ranges for the mark are from 0 (the worse) to 10 (the best). The intervals 0–4.9, 5–6.9, 7–8.9, and 9–10 are the different intervals that our evaluation system includes. To analyze these results, we have used the Analysis of Variance to check if the means of marks from Table 2 are equal. First of all, we have proved the homocedasticity or homogeneity of Variances using the Levene’s test, and we got that the value in the Sig. column is 0.765 which means that the variability of the marks before and after Bologna changes is about the same. The ANOVA concludes that there is a statistically significant difference between the students’ marks during the courses 2010–2011 and 2011–2012, and the 2013–2014 and 2014–2015 (see Table 3). What we appreciate with these results is that students get better final marks: for marks from 7 to 10 in 2010–2011, there were 4% of students, and 4.55% in 2011–2012 (for the first call). After Bologna Accord, these quantities changed to 47% in 2013–2014, and 15.38% in 2014–2015. If we make the calculation for the total number of students and the final results, we get that during the first period (2010–2012) 30.43% of the students failed, and during the second period (2013–2015) this quantity decreased to 7%.

So, we could think that this methodology make students to learn more and better, and have a better mark. We did not pay attention to 2012–2013, because it was the first time with the new degree subject, and the eight students were very good students, and not too much to be considered in this study results.

We have also taken the students’ satisfaction surveys carried out by our quality assurance service into account, to analyze the results of the new proposed methodology. These surveys include 11 questions:

1. The lecturer clearly presents and explains the contents of the course.

2. The lecturer resolves any students’ doubts and guides students in the development of their tasks.

3. The lecturer is well organized and structured with the classes activities.

4. The activities or tasks (theoretical, practical, individual work, group, etc.) are helpful to achieve the objectives of the course.

5. The lecturer promotes student participation in the development of educational activities.

6. The lecturer is available for consultation by students (tutoring, academic guidance).

7. He/she has facilitated my learning and with their help I have improved my knowledge, skills, or abilities.

8. The teaching resources used by the lecturer are adequate to facilitate learning process.

9. The literature and teaching materials provided are useful for performing all the suggested tasks and the learning.

10. Assessment and evaluation methods are according to the development of the subject.

11. My overall satisfaction level with the professor/lecturer has been good.

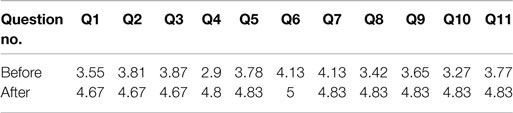

Table 4 shows the mean of the results of these satisfaction surveys. The first row indicates the number of question, the second (Before) is related to the mean of the results (using a Likert scale from 1 to 5) before the proposed changes, i.e., 2010–2011 and 2011–2012 academic years, and the third row includes the mean of the results for the following courses (excluding the 2012–2013 which is not representative).

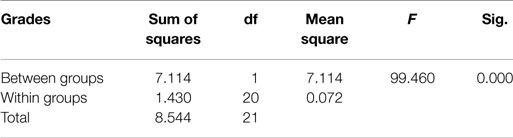

We have also made an ANOVA test with these data and the results indicate that there is a change (see Table 5). The variance between groups is bigger than the variance inside the groups and in any signification level. The ANOVA concludes that there is a statistically significant difference between the students’ satisfaction before and after changing the teaching–learning methodology.

Conclusion

The use of computers allows the students to have access to all the online tools and software oriented to the simulation of theoretical topics studied in theoretical classes, like the tension conditions to which the elements that compose the machines are submitted. Furthermore, students can optimize the use of the materials needed for machines construction and predict with sufficient accuracy their useful life.

What we propose to our students is the use of several IT tools, like the virtual environment (which includes files, questionnaires, or links), the spreadsheet, and specific simulation software to acquire the knowledge and competences to be an engineer.

Some of the disadvantages or difficulties that we founded using ICT are the following:

• The challenge presented by IT tools in an education sector. Sometimes traditional educational institutions were against the use of new tools, and not all educational institutions have an academic support area for software development.

• Ongoing activities should be perfectly organized and progressive so that the students should not become a mere passive spectator, but get the required competencies.

Conflict of Interest Statement

The authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

Acknowledgments

This work has been partially supported by Fundación Memoria D. Samuel Solórzano Barruso under the project FS/28-2014, and by the University of Salamanca, grants ID2014/0235, ID2014/0272, and ID2014/0273.

References

Alonso, F., López, G., Manrique, D., and Viñes, J. M. (2005). An instructional model for web-based e-learning education with a blended learning process approach. Br. J. Educ. Technol 36, 217–235. doi:10.1111/j.1467-8535.2005.00454.x

Bencomo, S. D. (2004). Control learning: present and future. Annu. Rev. Control. 28, 115–136. doi:10.1016/j.arcontrol.2003.12.002

Buitrago-Molina, J. T., Carvajal-Guerrero, J. S., and Zapata-Castillo, C. A. (2014). Virtual environment for local and remote control of a robot arm for support in engineering teaching. Tecno Lógicas 17, 67–74.

Caridade, C. M. R., Encinas, A. H., Martín-Vaquero, J., and Queiruga-Dios, A. (2015). CAS and real life problems to learn basic concepts in linear algebra course. Comput. Appl. Eng. Educ 23, 567–577. doi:10.1002/cae.21627

Cheetancheri, K. G., and Cheng, H. H. (2009). Spreadsheet-based interactive design and analysis of mechanisms using Excel and Ch. Adv. Eng. Software. 40, 274–280. doi:10.1016/j.advengsoft.2007.08.003

EHEA. (2010). European Higher Education Area Website 2010-2020. Available at: http://www.ehea.info

Escobar-Rodríguez, T., and Monge-Lozano, P. (2012). The acceptance of Moodle technology by business administration students. Comput. Educ. 58, 1085–1093. doi:10.1016/j.compedu.2011.11.012

García-Beltrán, A. (2006). Web assisted self-assessment in computer programming learning using AulaWeb. Int. J. Eng. Educ. 22, 1063–1069.

Gogan, M. L., Sirbu, R., and Draghici, A. (2015). Aspects concerning the use of the Moodle platform – case study. Procedia Technol. 19, 1142–1148. doi:10.1016/j.protcy.2015.02.163

Ibrahim, D. (2009). Using the excel spreadsheet in teaching science subjects. Procedia Soc. Behav. Sci. 1, 309–312. doi:10.1016/j.sbspro.2009.01.058

Ko, C. C., Chen, B. M., and Chen, J. (2004). Creating Web-Based Laboratories. London: Springer Science & Business Media.

Martín-Blas, T., and Serrano-Fernández, A. (2009). The role of new technologies in the learning process: Moodle as a teaching tool in Physics. Comput. Educ. 52, 35–44. doi:10.1016/j.compedu.2008.06.005

Moodle. (2012). Moodle Statistics. Available at: http://moodle.org/stats/

Norton, R. L. (2006). Machine Design: An Integrated Approach, Vol. 3. Upper Saddle River, NJ: Pearson Prentice Hall.

Poindexter, S. E., and Heck, B. S. (1999). Using the web in your courses: what can you do? What should you do? IEEE Control Syst. Mag. 19, 83–92. doi:10.1109/37.745773

Queiruga Dios, A., Gayoso Martínez, V., Encinas, A. H., and Hernández Encinas, L. (2012). “The computer as a tool to acquire and evaluate skills in math courses,” in 4th International Conference on Computer Research and Development, IPCSIT, ed. A. Wu (Singapore: IACSIT Press), 39.

Queiruga Dios, M., Hernández Encinas, A., Queiruga Dios, A., and Queiruga Dios, D. (2013). Motivational programme for undergraduate students. J. Teach. Educ. 2, 131–137.

Robertson, B. F., Walther, J., and Radcliffe, D. F. (2007). Creativity and the use of CAD tools: lessons for engineering design education from industry. J. Mech. Design 129, 753–760. doi:10.1115/1.2722329

Torres, F., Candelas, F. A., Puente, S. T., Pomares, J., Gil, P., and Ortiz, F. G. (2006). Experiences with virtual environment and remote laboratory for teaching and learning robotics at the University of Alicante. Int. J. Eng. Educ. 22, 766–776.

Keywords: mechanical engineering, design of machines, assessment, skills and competences, Moodle platform, questionnaires

Citation: Queiruga-Dios A, Izard-Anaya E, Bullón-Pérez JJ, Hernández-Encinas A and Martín-Vaquero J (2015) Case Study: Online Learning for Design and Calculation of Machines. Front. ICT 2:27. doi: 10.3389/fict.2015.00027

Received: 27 May 2015; Accepted: 06 November 2015;

Published: 25 November 2015

Edited by:

Leman Figen Gul, Istanbul Technical University, TurkeyReviewed by:

Aydin Oztoprak, TOBB University of Economics and Technology, TurkeyEric Fouh, Virginia Tech, USA

Copyright: © 2015 Queiruga-Dios, Izard-Anaya, Bullón-Pérez, Hernández-Encinas and Martín-Vaquero. This is an open-access article distributed under the terms of the Creative Commons Attribution License (CC BY). The use, distribution or reproduction in other forums is permitted, provided the original author(s) or licensor are credited and that the original publication in this journal is cited, in accordance with accepted academic practice. No use, distribution or reproduction is permitted which does not comply with these terms.

*Correspondence: Araceli Queiruga-Dios, queirugadios@usal.es

Araceli Queiruga-Dios

Araceli Queiruga-Dios Eulalia Izard-Anaya2

Eulalia Izard-Anaya2

Juan José Bullón-Pérez

Juan José Bullón-Pérez Ascensión Hernández-Encinas

Ascensión Hernández-Encinas Jesús Martín-Vaquero

Jesús Martín-Vaquero